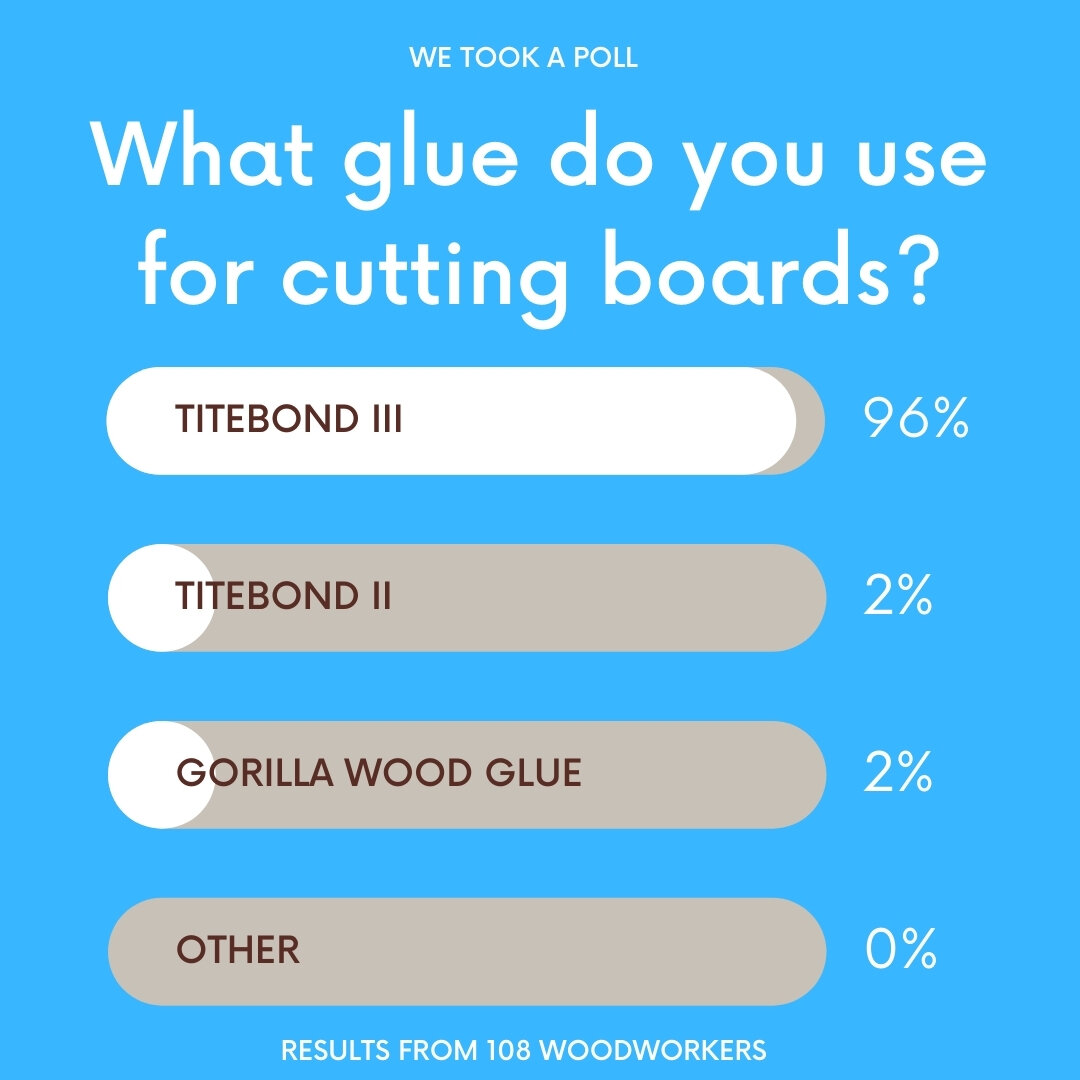

What is the Best Glue For Cutting Boards?

The best wood glue for cutting boards is Titebond III Ultimate Wood Glue and is the most widely used glue by woodworkers. Titebond III is FDA approved for indirect food contact, waterproof, and is non-toxic. When polling woodworkers specializing in cutting boards, they chose Titebond III 96% of the time. Titebond III is chosen by woodworkers for cutting boards for many reasons. The main reasons are that it has been proven to be waterproof as well as FDA approved for indirect food contact. These two key features make it perfect for cutting boards and it has become the number one choice for woodworkers. Another benefit of Titebond 3 which helped when I created my first cutting board was the longer open assembly time allowing up to 25 minutes.

The best way to apply glue for cutting boards.

The best applicators for gluing up cutting boards are using a roller, brush, or dedicated roller bottle. When gluing cutting boards its essential that you are applying enough glue to eliminate any gaps and prevent future cracks. Listed below are a few tools that make it easier to apply glue to your cutting board sections or panel glue ups. I personally have a few glue rollers, Rockler glue brushes, and Fastcap Glue Bot bottles which have made it much easier to apply glue than the original bottles. If I were to make multiple cutting boards, I would definitely buy a glue roller bottle.

Best Applicators for Gluing Cutting Boards

Best clamps for gluing a cutting board!

The best clamps for gluing a cutting board are parallel clamps or bar clamps. Parallel clamps are the best at providing even pressure, especially if you are assembling cutting boards 1 inch thick or larger. Parallel clamps also provide a flat surface to clamp your cutting board as well as remaining upright on your assembly table in contrast to f-style clamps. Bar clamps are also good for cutting boards and have some of the same benefits of a parallel clamp but with some limitations. The downsides of bar clamps for cutting boards are the limited clamping surface for thicker boards as well as lower clamping pressure.

How to protect your clamps from glue!

The best way to protect your clamps from glue squeeze out, especially when gluing up your cutting board is to use painters tape. Before clamping your workpiece, place painters tape on the bar of your clamp roughly the length of what you plan to clamp. The painters tape will prevent glue from drying on you the bar of your clamps and will save you time by easily removing the tape. This trick has help me keep my clamps from being covered in glue and is an easy way to save some time in the workshop.

How to clean up glue on a cutting board?

The best way I have found to clean up glue when assembling a cutting board or panel glue up is using a drywall putty knife and a cabinet scraper. Using a drywall putty knife while the glue is slightly hardened but not completely dry will get the majority of the glue off your workpiece. Make sure to only use the putty knife while the glue is still soft, if not you may end up ripping off the top layer of wood. Once the glue dries using a cabinet scraper will easily scrape off the glue and leave your cutting board or workpiece smooth and glue free. A cabinet scraper is prefect to remove that thin layer of glue on your cutting board before you flatten it on your drum sander or planer saving you additional maintenance or costs for sandpaper and planer blades.

How to store your glue for a longer shelf life.

An easy way to extend the shelf life of your glue is to have a dedicated tote that you bring inside while not being used in your workshop. Titebond III does have a limited shelf life of 24 month but that also depends on how you store the glue. Titebond recommends storing the glue in tightly closed containers below 75 degrees. If you store your glue in your garage, or workshop that is not heated or cooled you may be decreasing the shelf life of the glue. I personally live in the Mid-Ohio Valley which experiences multiple seasonal changes and I have experienced issues with my glue freezing and thawing as well as being stored in high temperatures. Because of that, I have had to throw away glue bottles that I left in my garage for a while that was before the advertised shelf life.

Related Articles

If you have any questions, comment below.

Let’s talk about it!