How to Calculate Board Feet or Linear Feet

Difference Between board feet and linear feet?

The difference between board feet and linear feet is that the calculation of board feet considers volume. Linear feet is a standard measurement for the length of a board. As such linear feet does not take into consideration the width or thickness of a board whereas board feet use width and thickness to calculate the volume of a board. It is sometimes used when pricing S4S lumber since it is a uniform thickness and width. Typically, if purchasing directly form a hardwood lumber yard or dealer they will be using board feet for pricing.

Board Feet Calculation

Board feet is calculated by multiplying a boards thickness in inches (T) by the width in inches (W) by the length in feet (L) and dividing by 12. Board Feet = ( T x W x L ) / 12

One thing to note when calculating board feet is to use the nominal thickness which is before any dimensioning occurs. For instance, a dimensioned hardwood board that is ¾ in thick would have a nominal thickness of 1 inch. Most hardwood lumber is sold by the board foot which is actually a measure of volume. The main reason hardwood dealers sell by the board foot is because hardwood lumber comes in varying thicknesses and widths.

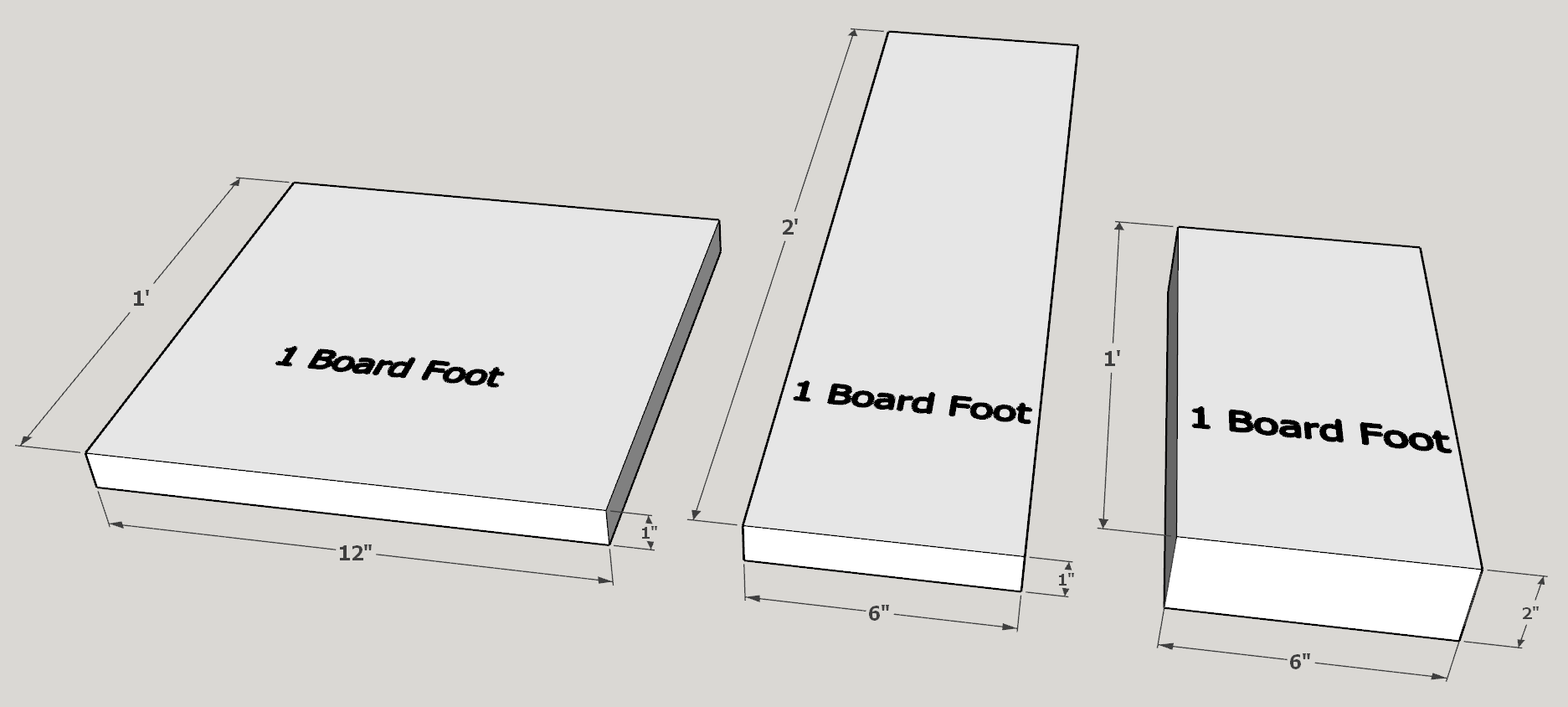

Examples of 1 Board Foot

When you look at hardwood boards and try to compare board feet it can be quite puzzling as a board foot can take many different shapes. The above image shows just how 1 board foot can vary depending on the width of a board or thickness.

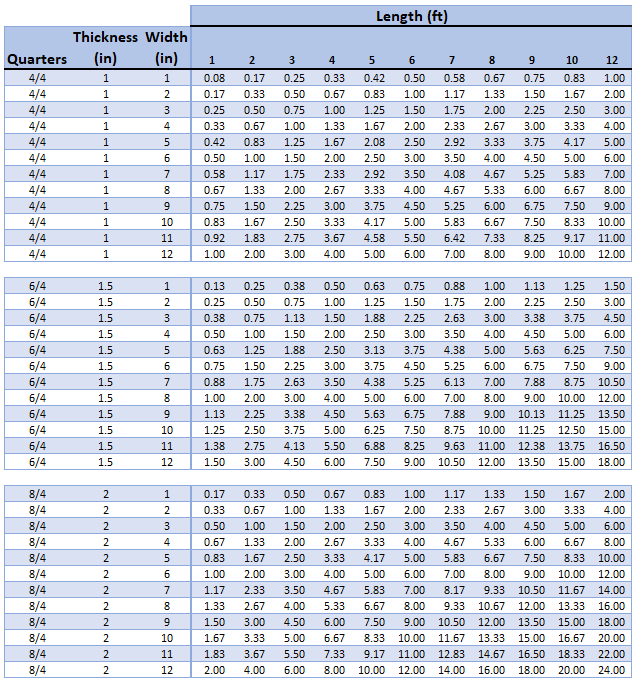

Quick Chart For Board Foot Calculations

Why is board feet calculated based on nominal size?

Hardwood dealers calculate board feet using nominal size due to the fact that hardwood can be purchased at various stages of dimensioning. Nominal sizes are the size of a board before it is dimensioned such as planed to thickness or straight lined ripped. You can purchase the lumber RGH, S2S, S3S or S4S all with varying sizes. Sometimes, if purchased rough on a 1-inch nominal thickness board you are able to yield more than the standard ¾ inch thickness. Therefore, all hardwood lumber yards and dealers use the nominal thickness of a board to calculate board feet and for pricing.

How much extra board feet should I buy for a project?

The amount of extra board feet that you need to purchase for your project depends on a few factors, but typically you should purchase 10% to 20% extra. The factors that you should take into consideration would be the grade of lumber, the stage of dimensioning (S4S, S3S, S2S, or RGH) as well as specific sizes needed for a project. Also, if you are purchasing hardwood lumber other than FAS grade lumber you should account for additional waste. If you purchase rough cut lumber (RGH) you should factor in the amount of waste involved in dimensioning and removing any knots, twists or bows. Where you could get away with purchasing the least amount of wood is if you plan very carefully and find a hardwood dealer that sells S4S or surfaced 4 sides material that is already dimensioned to final sizes.

Related Articles

If you have any questions, comment below.

Let’s talk about it!